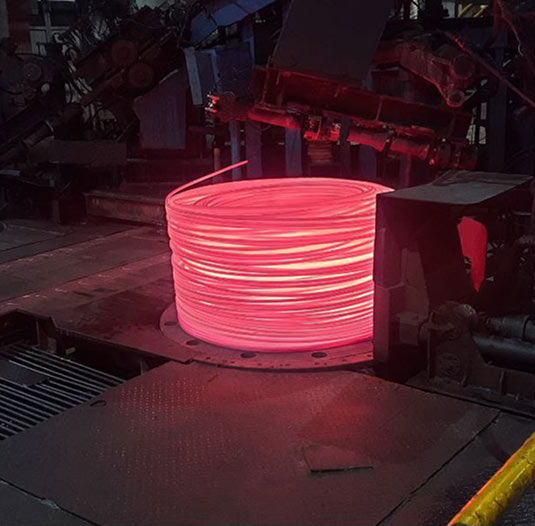

Aligned with our reputation of producing durable products, we produce specialty alloy steel long products that are known for their improved strength and are resistant to corrosion. We produce wide variety of grades of Alloy Steel in different shapes & sizes to meet multiple end use applications.

340x400 mm

Largest Rolling size for higher reduction

5.5-200 mm

wide range & grades of rolled products

Level 2

Automation - In Steel Melting

Shop-2 and Heavy Bar Mill

Steel Melting Shops & Rolling Mills

Engineered for Strength and Performance

Steel Melting Shops & Rolling Mills

Engineered for Strength and Performance

- Coil Spring

- Piston

- Tyre Cord & Tyre Bead

- Gear

- Ring Gear

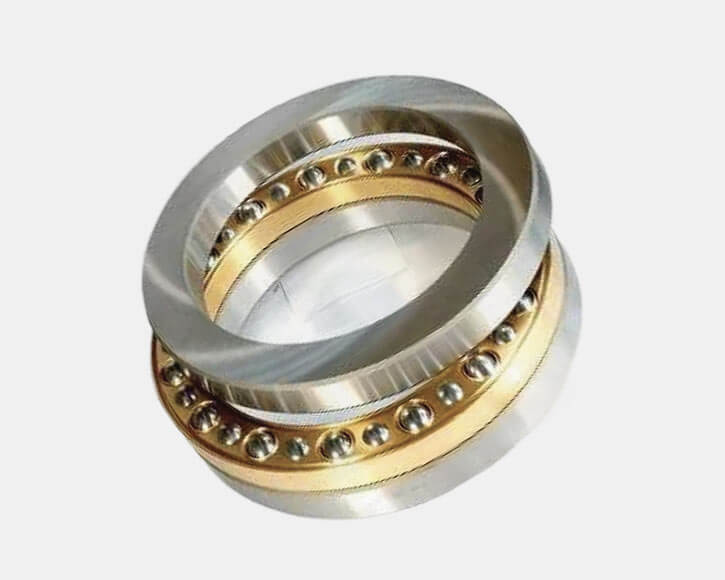

- Bearing